HIP TECHNOLOGY

ABOUT HIP

TECHNOLOGY INTRODUCTION

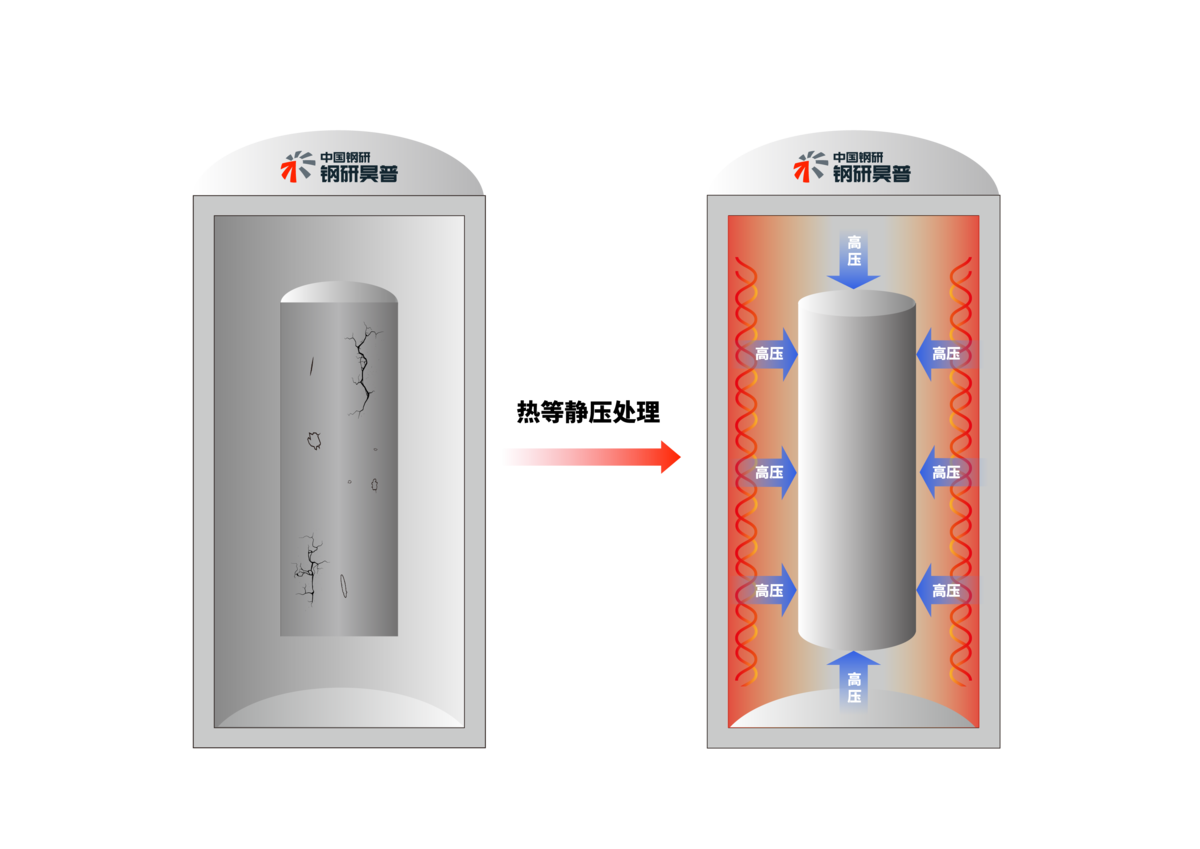

01. What is HIP?

A special heat treatment process for improving the quality of materials

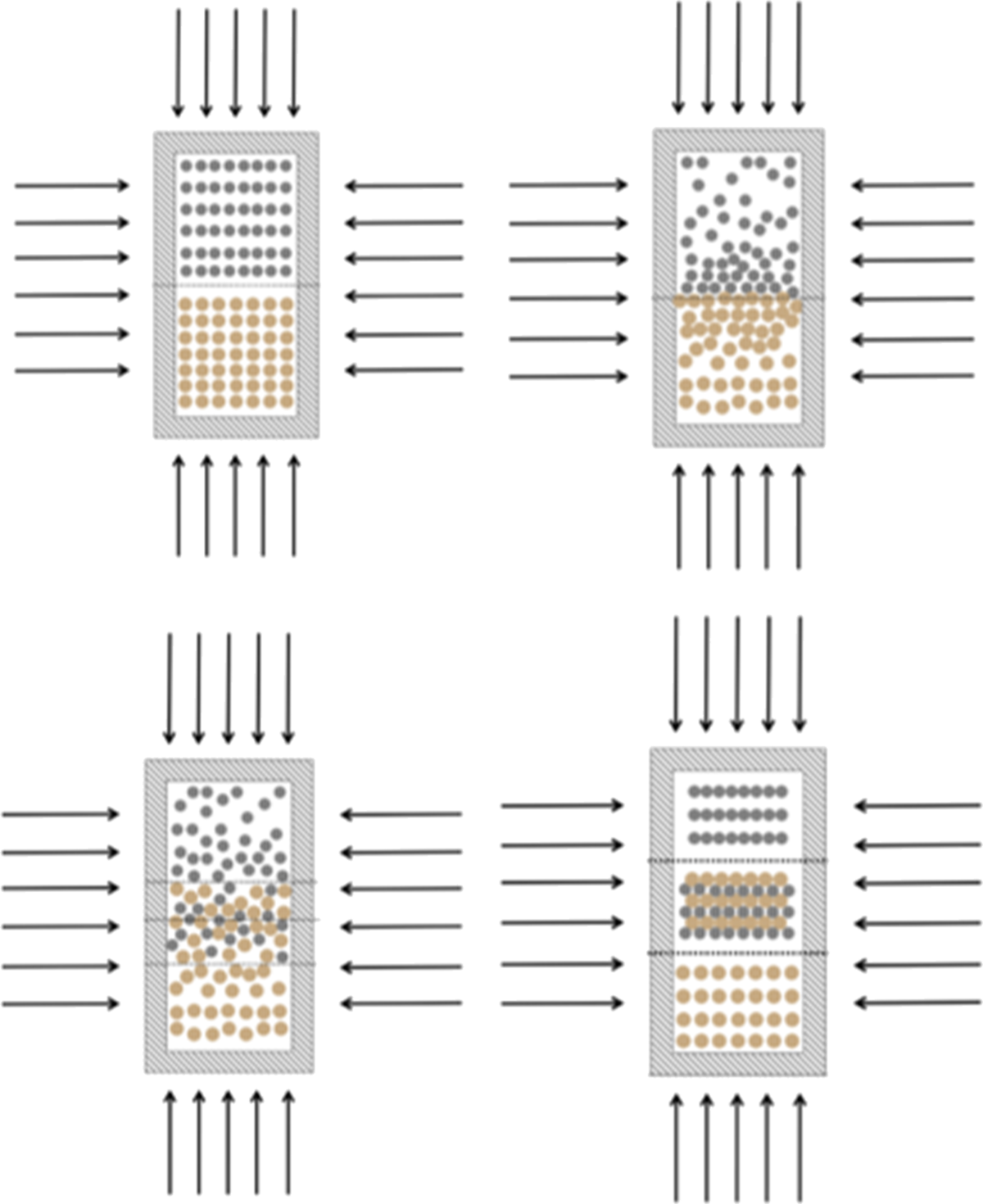

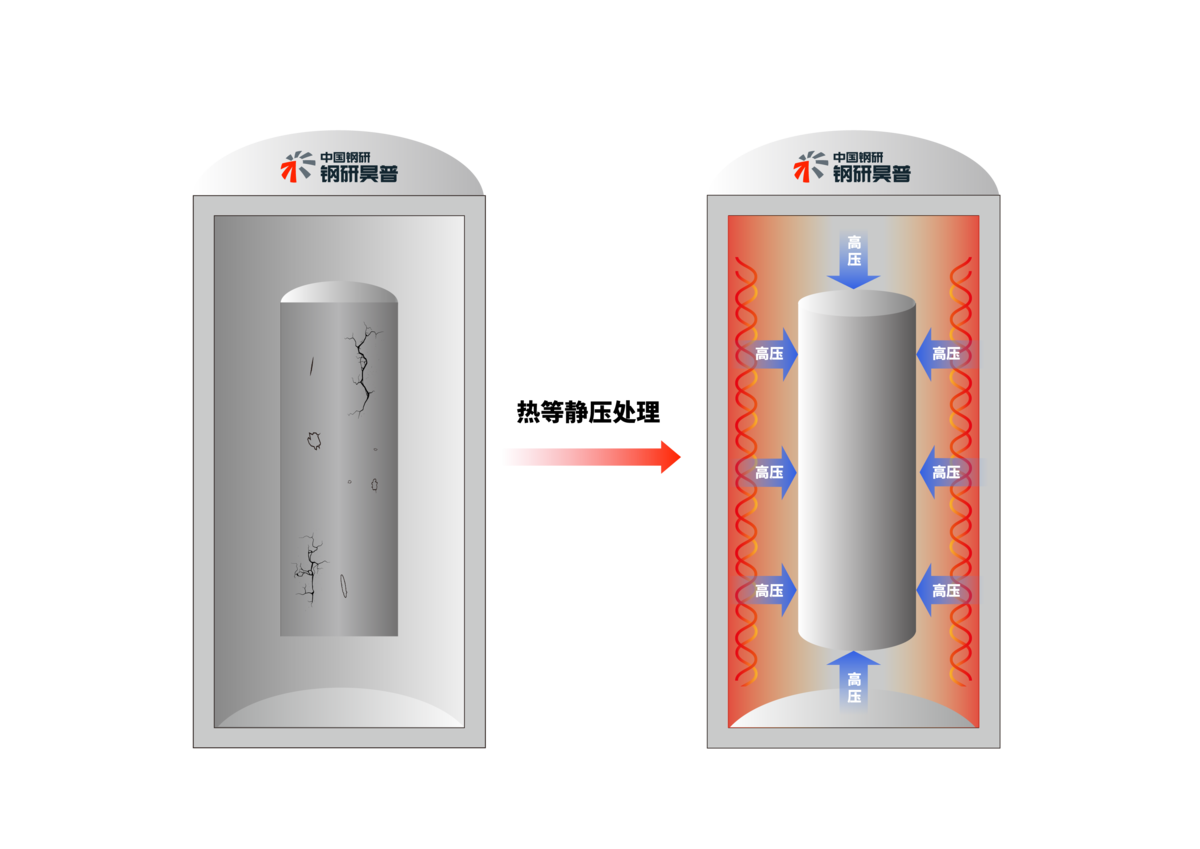

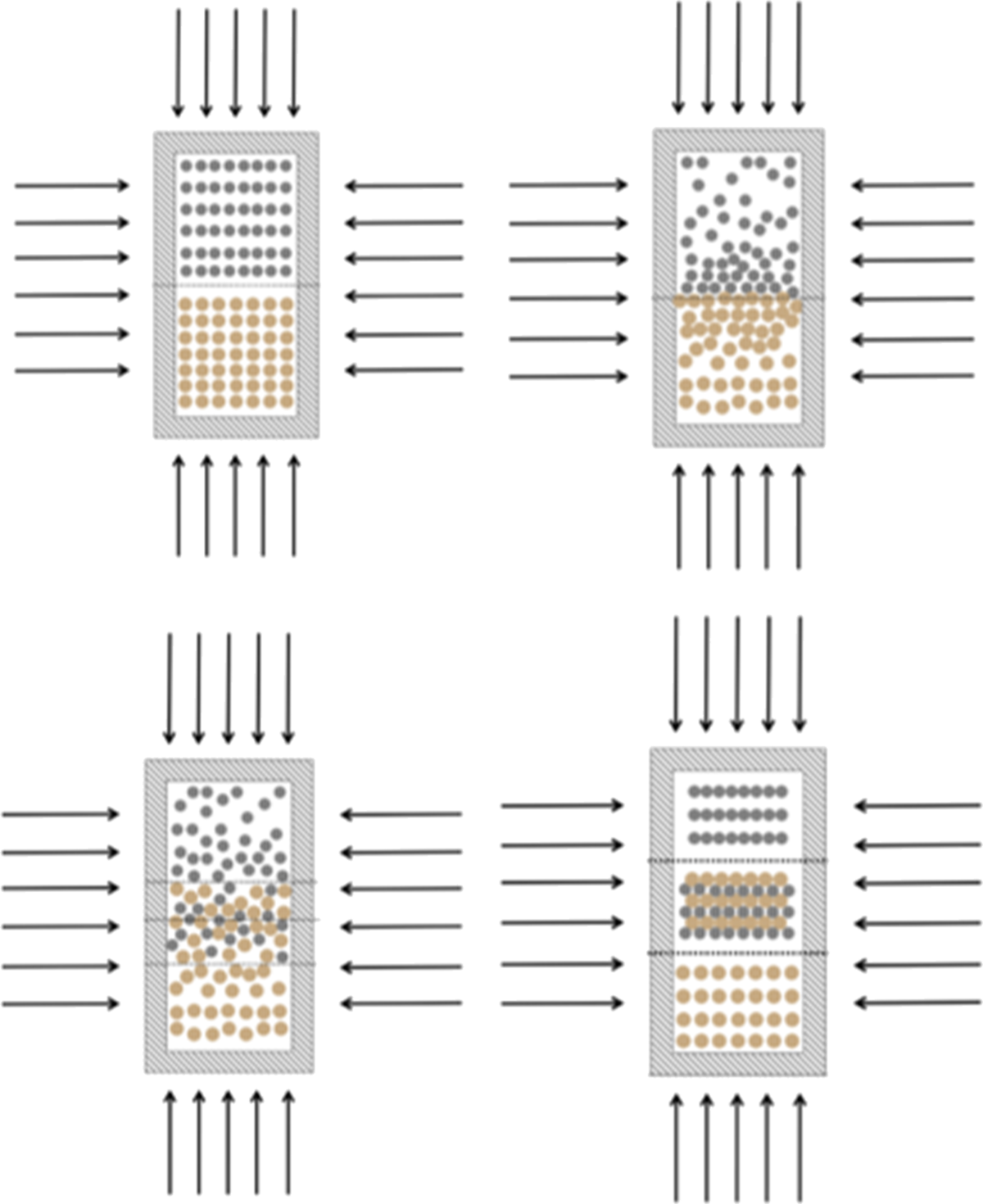

Hot Isostatic Pressing (HIP) is a special heat treatment process for metal or ceramic materials, which is a means to produce high-performance materials. The technology can be used for powder metallurgy molding , densification of the molded castings or 3D-printed products, or diffusion bonding of two or more different materials. After HIP treatment, the wear resistance, corrosion resistance and mechanical properties of the material will be greatly improved, and the fatigue life can be increased by 10~100 times.

Processing characteristics:

- High Temperature - reach up to 2000℃

- High Pressure – reach up to 200 MPa

- Isostatic Pressure - Using inert gas as the pressure transfer medium, and the same pressure is applied evenly to the surface of the parts from all directions

Main application material system:

Superalloy, titanium alloy, aluminum alloy, copper alloy, refractory metal, hard alloy, stainless steel, corrosion resistant alloy, ceramics, composite materials, electronic materials, functional materials, etc.

02. Why use HIP?

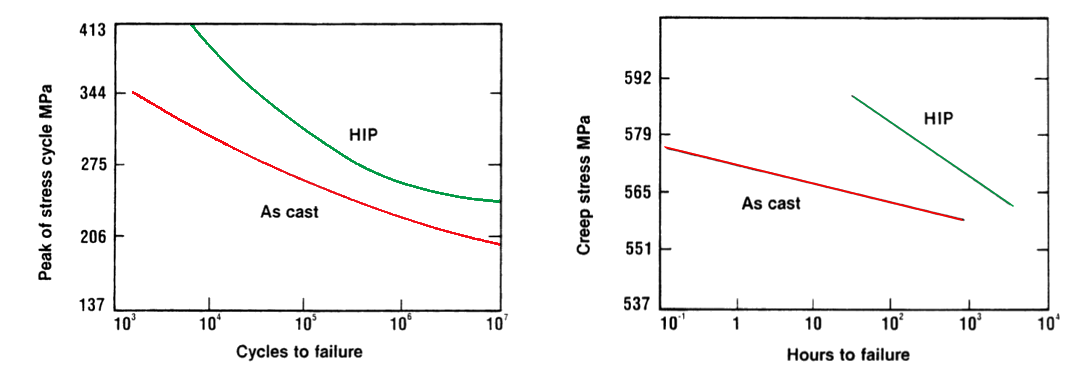

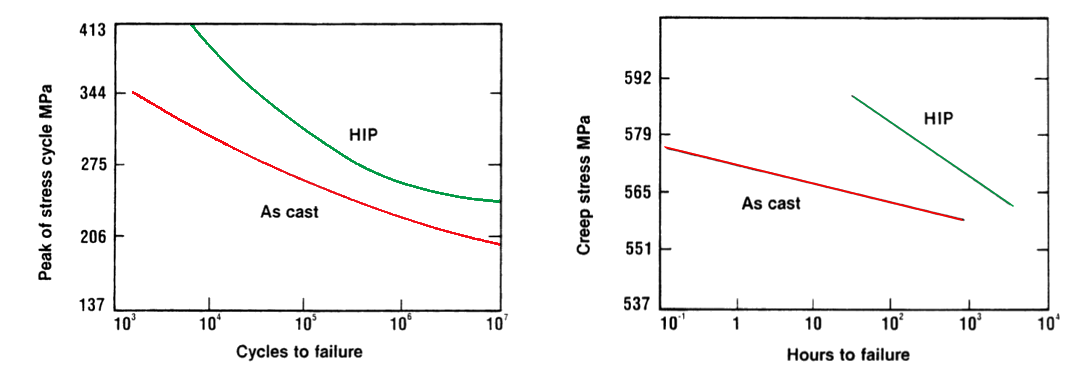

Greatly improves the mechanical properties of the material and increases its fatigue life by 10~100 times

As we all know, any materials have a certain fatigue life, could not be indefinitely used. There are two fundamental reasons for material failure. One is composition changes in the internal structure of the material. The new composition cannot achieve the appropriate performance, and the material immediately fails. Another more common reason is the internal residual impurities, tiny cracks, voids, residual stresses etc. in materials, to form the performance break point, which we call “material defects”. When materials work, such as the high temperature circulation loop, the stress concentration effects at the location of the performance break point, eventually make the material fracture failures. So far, none of the traditional molding methods can directly eliminate the residual defects in the material, and the subsequent processing is always needed.

Of course, in a normal working environment, there is no need to put forward excessive requirements on the performance of the material. Some defects are allowed as long as they do not affect the use of the material. But in some special working environment, such as aircraft engines, nuclear reactors, gas turbine, offshore oil exploitation, and so forth, the material need to bear high temperature, pressure, amplitude or corrosive environment. On this occasion, very high material performance are required, in addition to high strength, toughness, corrosion resistance, high stability is necessary. At this point, it becomes particularly important to eliminate the internal defects of the material.

As a special metal heat treatment process, HIP now is the most effective heat treatment method to eliminate the internal defects of materials, and it is also the material forming method to minimize the internal defects of materials. Therefore, it becomes a routine processing procedure for key parts in various fields worldwide.

ACCORDING TO THE NEEDS OF PRODUCTS TO BE PROCESSED

HIP TREATMENT SERVICES CAN BE DIVIDED INTO THE FOLLOWING THREE CATEGORIES:

DENSIFICATION

Eliminate internal defects and achieve theoretical density

DIFFUSION BONDING

Integration of two or more different metals

HIP-Near Net Shape

HIP Near net shape powder molding, high performance, cost effective

- DENSIFICATION

Eliminate internal defects and achieve theoretical density

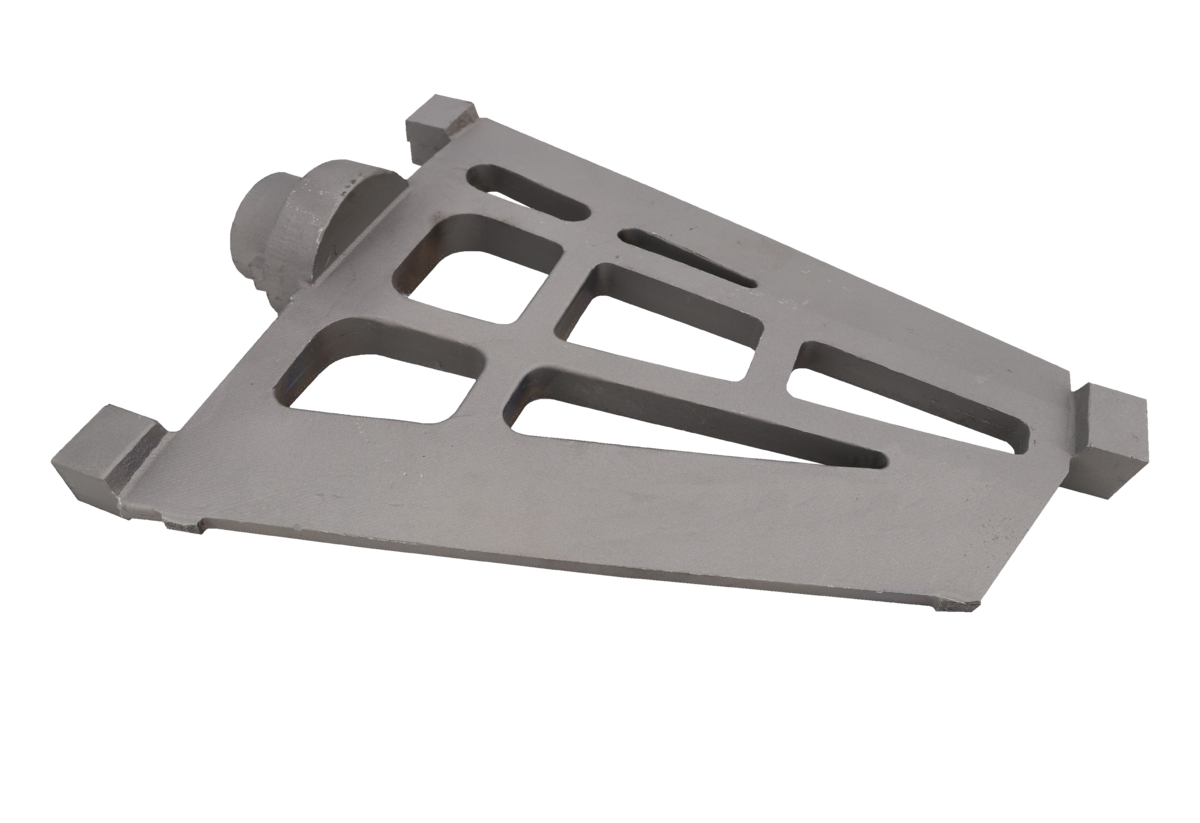

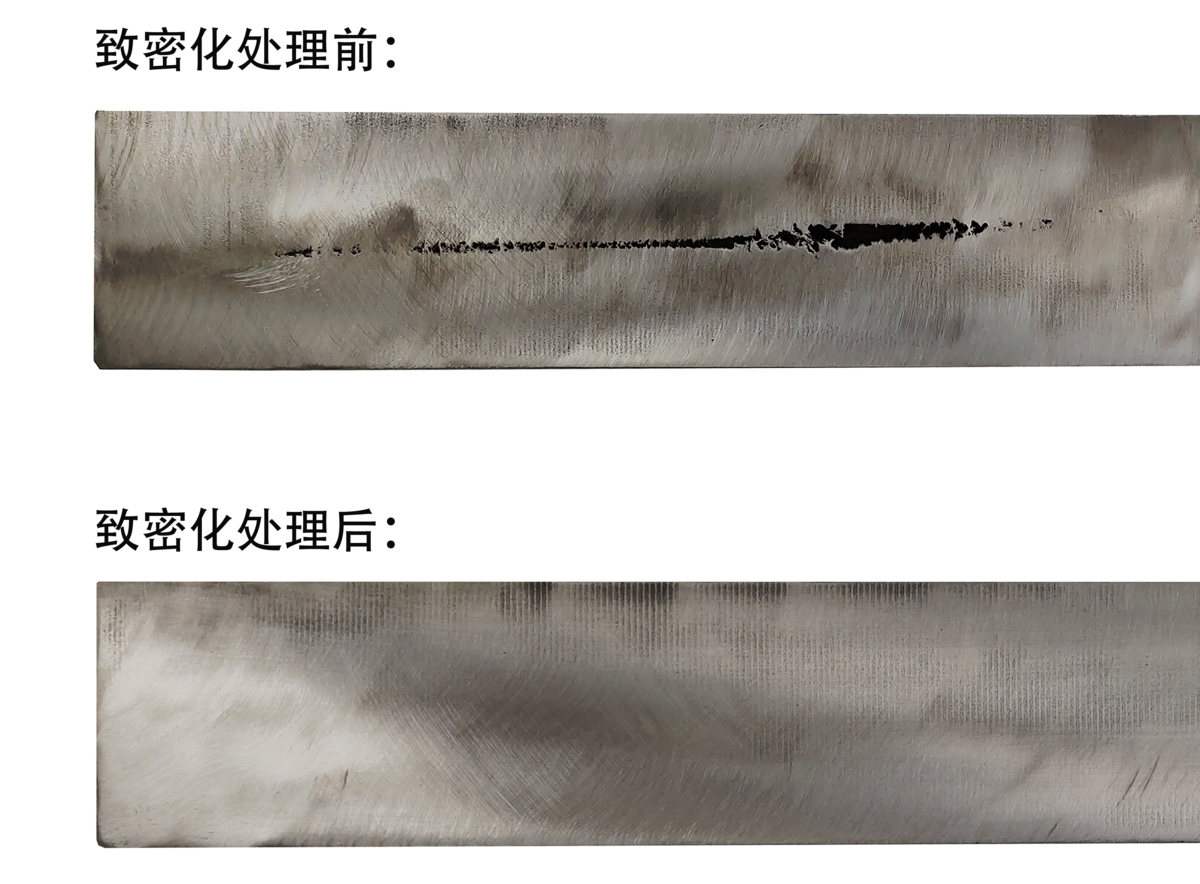

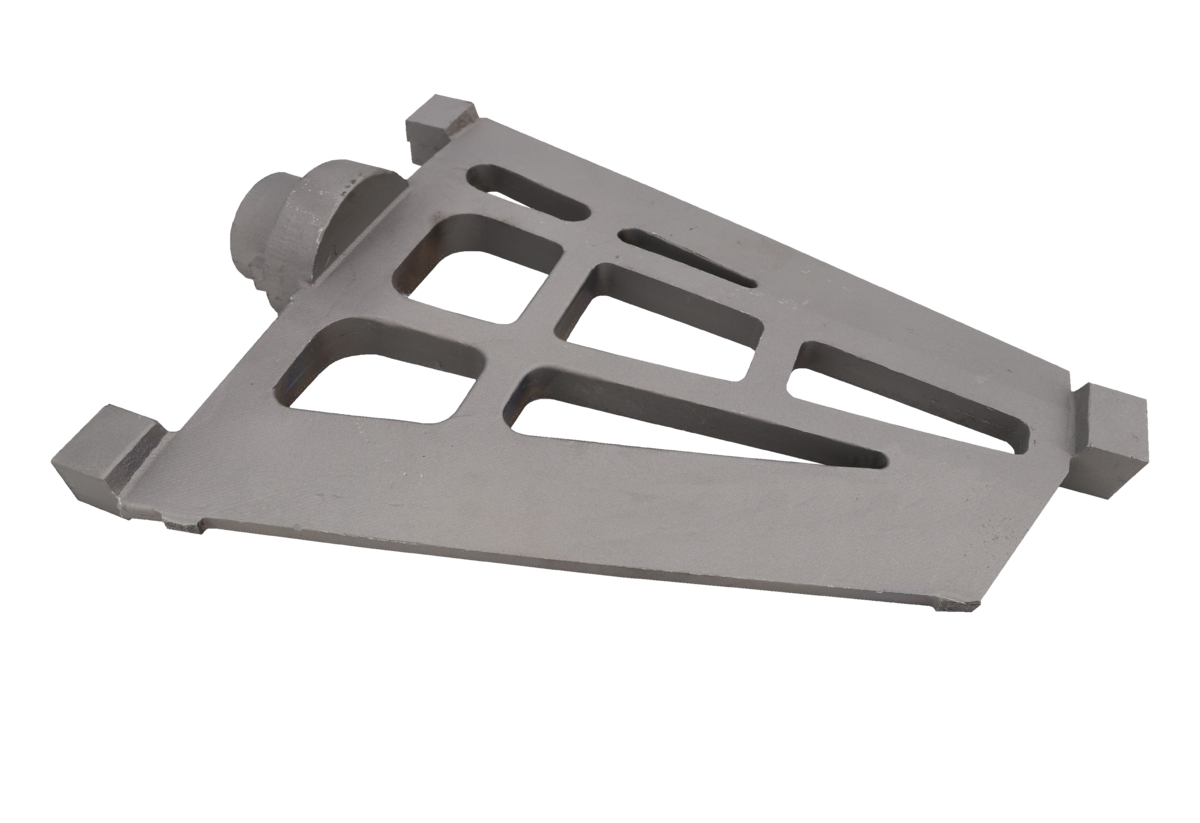

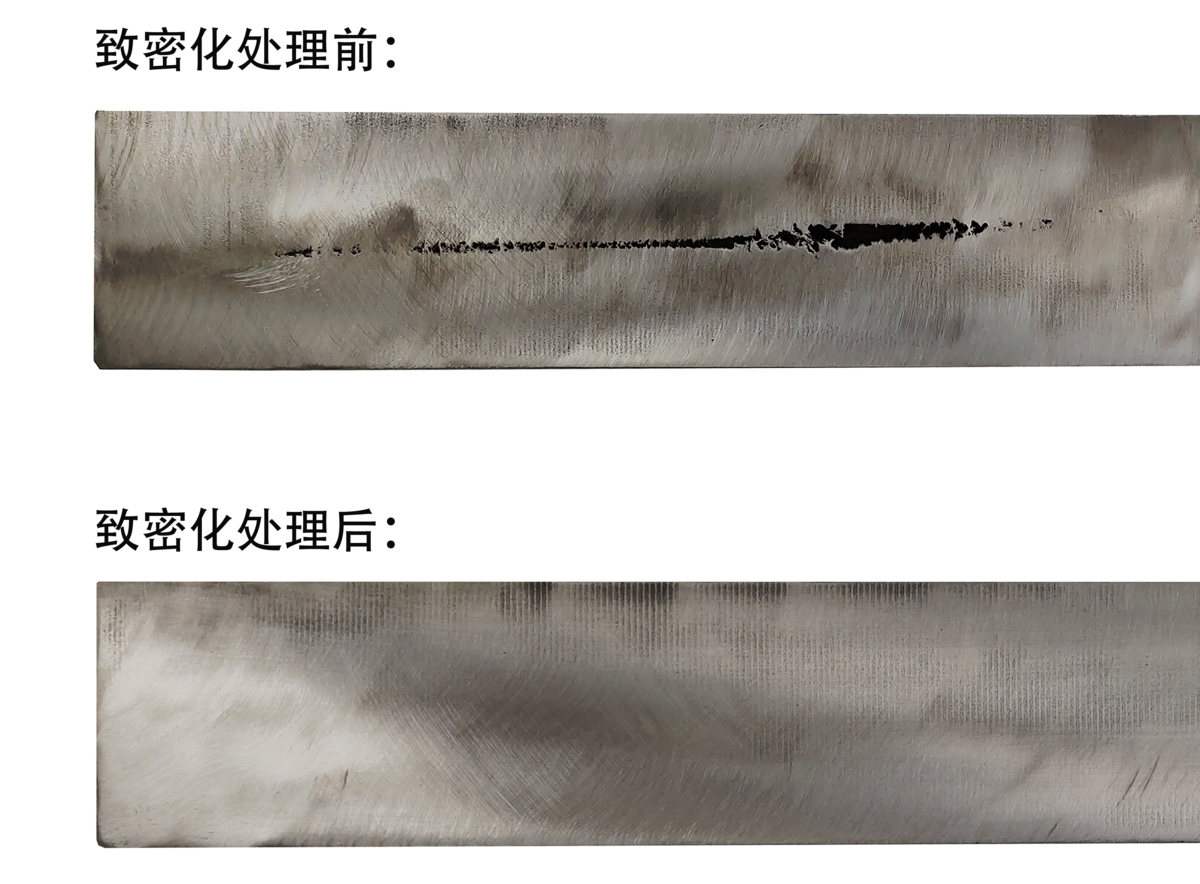

During the service process of the material, the residual pores and tiny cracks in the material are not only the fracture initiation points, but also the wear and corrosion initiation points. In aircraft engine, nuclear reactor, gas turbine and other complex working environment, the material fracture failure will cause very serious consequences. After the HIP treatment, the internal structure of the material densifies, all pores and defects disappear, forming a uniform and dense texture, which greatly improves the wear-resistance, corrosion resistance, mechanical properties and fatigue strength of the material.

In the casting process, due to the uneven temperature diffusion of the material during cooling, internal porosity, segregation, shrinkage cavity, microcrack and other inherent defects of the process will be produced, which will reduce the material mechanical properties, service life and stability. Similarly, in metal injection molding and 3D printing processes, there are also problems such as loose internal structure of materials, residual defects and internal stresses.

HIP densification processing refers to putting the castings, MIMs, 3D-printed products, or other products with defects inside, in the HIP fuanace, by inert gas as the transmission medium, exert the high temperature, high pressure and isostatic pressure on their surface. Such exertion force products deformed under the solid phase, on the atomic diffusion level, pore and tiny crack thus disappear. Due to the elimination of the material internal fracture initiation point (stress concentration point), the overall performance of products are greatly improved.

- Internal defect elimination -- shrinkage porosity, shrinkage cavity, segregation, etc.

- Greatly enhance the fatigue life -- 10~100 times

- Improve ductility and fracture toughness

- Reach the theoretical density

- Improve the wear resistance, corrosion resistance

- Eliminate residual stress in the material

In recent years, with the overall improvement of product quality, the densification processing business has gradually expanded to more civilian areas. Uphold the responsibility of a leading enterprise,HIPEX persist in pursuing the largest processing capacity and processing range, to provide customers with the most cutting-edge technology and the most reliable quality of service.

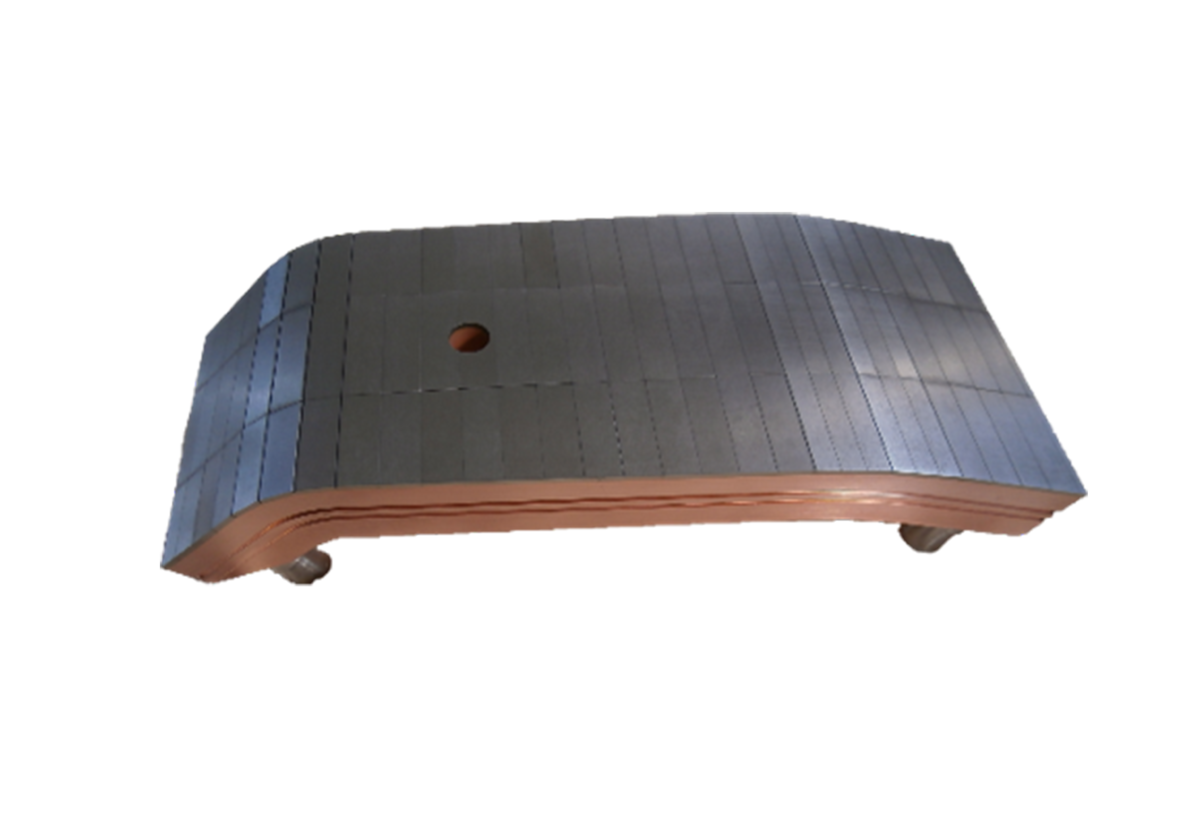

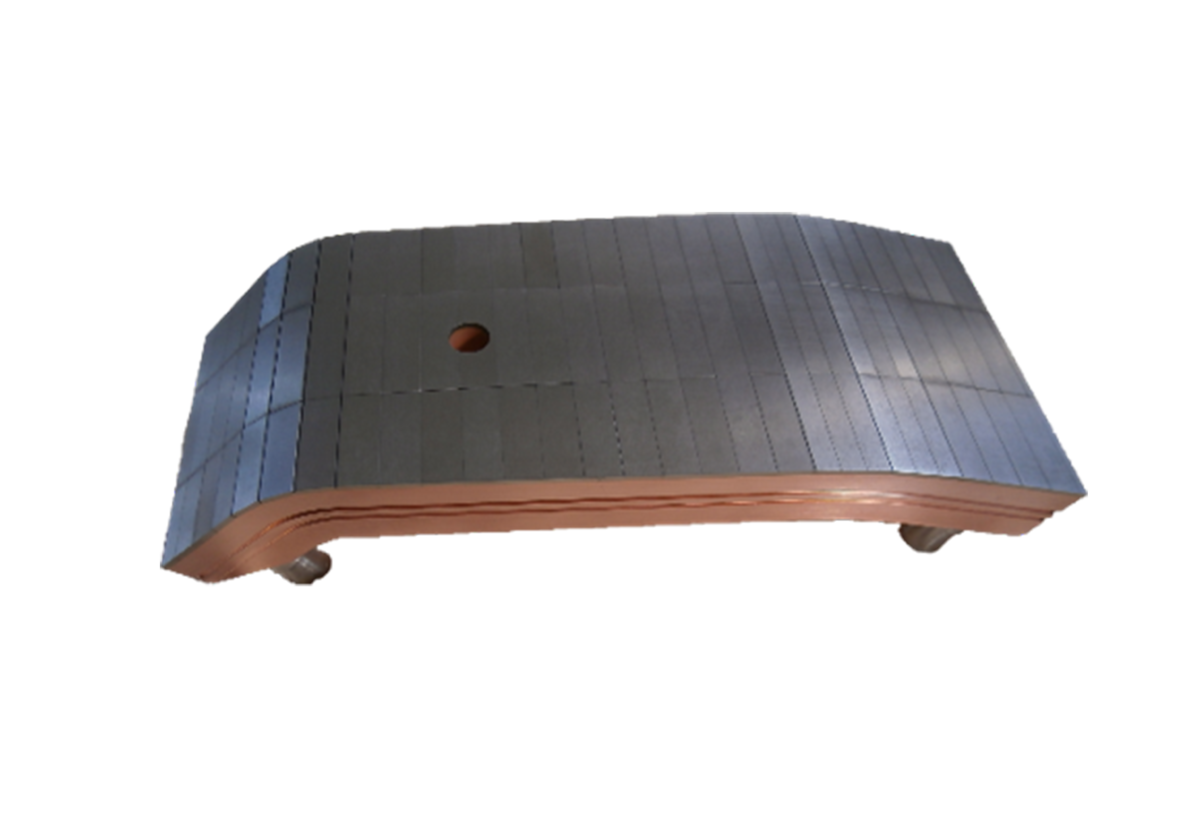

- DIFFUSION BONDING

Integration of two or more different metals

In industrial manufacturing, engineers often bond different materials together to get the best combination of material properties. However, the conventional welding method is often unable to achieve or the effect is not good, especially for the joint of irregular parts or large parts. Through the application of high temperature and high pressure, hot isostatic pressing can realize the diffusion connection between two or more kinds of metal materials or ceramic materials at the atomic level, so that a variety of materials are integrated. Compared with other connection technologies, the interface of the two materials is tightly bonded without defects, and the properties of the junction are indistinguishable from the base material.

- When connecting same materials, no liquid phase present throughout the process. The interface bonding strength is equivalent to the base metal, the interface can achieve good metallurgical bonding.

- When connecting different materials, the interface performance is not lower than the lower one of the two materials

- Connecting parts with complex shapes and achieving precise shape control

- Connecting multiple parts in one process

- Quickly achieve a large area of connection

- Connect brittle metals or metals with a large melting point difference that cannot be connected by conventional welding methods

- Small pores or cracks outside the connection area are eliminated due to the high and uniform isostatic pressure applied.

- No weld, heat affected zone, surface pores, inclusions, underbite, cracks and other defects produced in the traditional welding process

Due to the different thermal expansion coefficients of different metals, dislocations and internal stresses will be generated at the interface when heated, which will affect the connection effect. HIPEX engineers have made leaps and leaps in diffusion bonding technology, developing the bonding technology between different materials, and applying the technology to a wide variety of materials, such as copper, stainless steel, tungsten alloy, cobalt-based alloy, nickel-based alloy, chromium, molybdenum, etc.

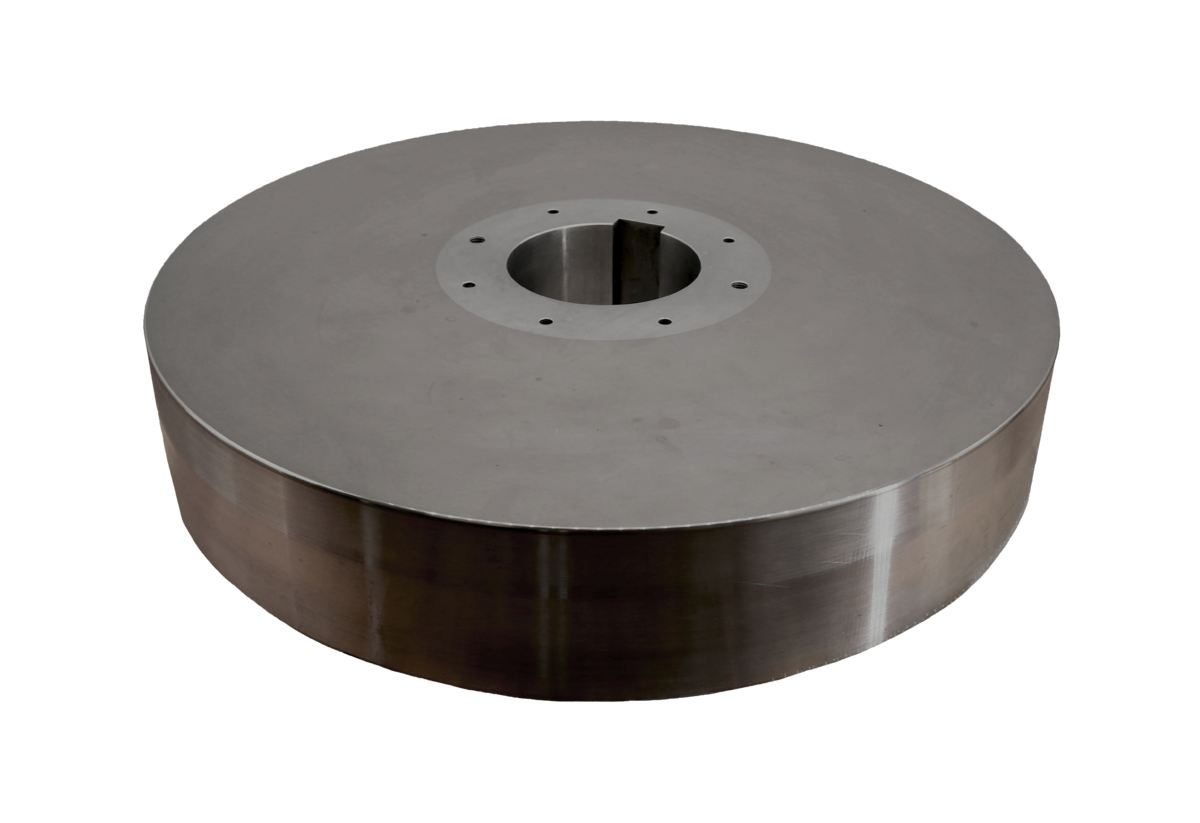

- HIP - Near Net Shape

HIP-NNS powder molding, high performance, cost effective

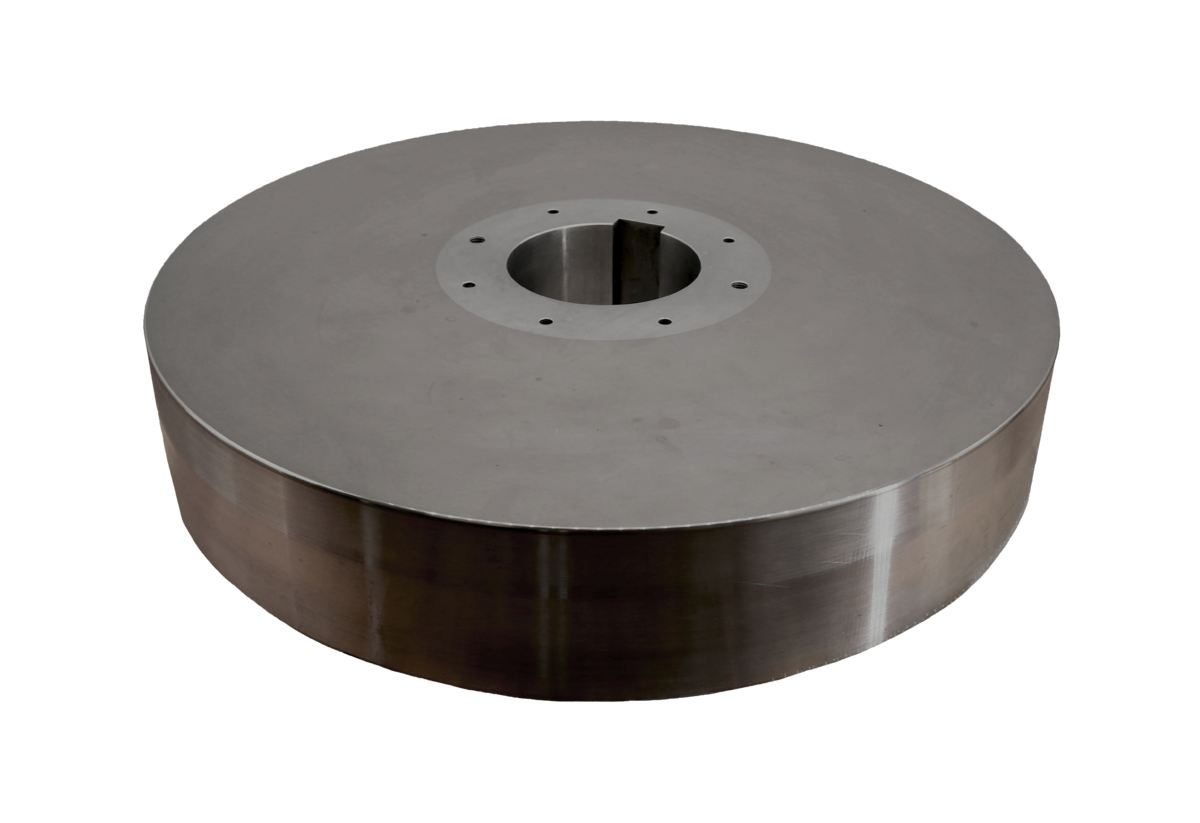

HIP-NNS powder metallurgy refers to the use of HIP process directly sintered the product into a specified shape. In addition to the advantages of traditional powder metallurgy, HIP technology can consolidate the powder material into a denser, higher performance finished product.

•Flexible design -- Designed to nearly the same shape as the final product, reducing raw material waste, machining procedures, and shipping time.

• Fine and uniform grain size, with isotropic material properties - Improved wear resistance, corrosion resistance, mechanical properties, fatigue life.

• For refractory materials – Because of high pressure, 0.8 times of the melting point is enough.

• Uniform and densified internal texture -- No effect on ultrasonic testing.

• No liquid phase - Minimizes segregation and improves corrosion resistance.

• Prepare bimetallic ingot billets - Bimetallic materials can later be processed by forging and extrusion.

CONTACT US

010-62181121

info@